Last Updated on July 16, 2023 By Emma W. Thomas

The best plywood for roofing depends on various factors, including the specific requirements of your project. However, a common and widely accepted choice for roofing is CDX plywood. CDX stands for “C-D Exposure,” indicating its durability and suitability for exterior applications. CDX plywood is made with multiple layers of wood veneers, with the letter “C” referring to the grade of the face veneer and the letter “D” representing the grade of the back veneer.

Types Of Plywood That Can Be Used In Roofing

There are various types of plywood suitable for roofing. These include:

Fire Retardant Plywood (FRT Plywood)

This type of plywood can be a lifesaver in times of fire crisis. It goes through treatments different from other plywood types, making it fire-resistant, weather-resistant, waterproof, and termite and borer-proof.

Cdx Grade Plywood

CDX plywood is a grade mostly for exterior purposes. C indicates the grade of the front side, D for the backside, and X shows the glue used to bond the two layers. The grades are from A to D, with A beings the best, i.e. free of knots and any other imperfection, and D is the least grade, meaning it is considered defective and un-sanded.

You can buy CDX with an A grade on the top+ and a lower grade on the backside. When roofing, the top part with higher grade faces outside while the other side with lower grade faces inside the roof.

Construction Structural Plywood

This is multipurpose plywood due to its strength, performance, and durability in building applications. It is also known as Marine Grade Plywood as it is used for marine applications such as ships and ships parts.

Based on the application, you can opt for either type A or Type B-bond structural plywood. Type A is stronger and more durable than type B, thus suitable for exterior applications. Type-B can also be used for external applications though it might not last long.

General Plywood

This is the least suitable plywood for roofing but can still work if well maintained. Mostly, the plywood is used for interior works such as tables, windows, and doors as they are not very strong as construction structural plywood.

How To Choose The Best Plywood For Roofing?

Choosing the best plywood for roofing requires considering several factors. Here’s a guide to help you make an informed decision:

- Plywood Grade: Opt for plywood specifically designed for exterior or roofing applications. Look for grades such as CDX (exposure durability), which indicates resistance to moisture and weather elements.

- Thickness: Determine the appropriate thickness based on your local building codes and the span of the roof. Thicker plywood provides better strength and durability.

- Plywood Type: Choose plywood that is suitable for roofing, such as OSB (oriented strand board) or CDX plywood. These types are commonly used and have proven track records for roofing applications.

- Moisture Resistance: Ensure the plywood has moisture-resistant properties, as roofs are exposed to weather conditions. Look for plywood treated with water-resistant coatings or opt for marine-grade plywood.

- Quality and Certification: Check for plywood with recognized certifications, such as APA (The Engineered Wood Association) certification. This ensures the plywood meets industry standards for quality and performance.

- Cost: Consider your budget, but prioritize quality and durability over cost. Investing in higher-quality plywood can lead to long-term savings by reducing the need for repairs or replacements.

- Supplier Reputation: Purchase plywood from reputable suppliers or manufacturers known for producing reliable and high-quality roofing materials.

What Is The Required Measurement For Roofing Plywood?

Plywood comes in 4 b 8 feet sheets but with varying thicknesses. For roofing, you need 3/8th of an inch thickness. The most common thickness is half an inch or 5/8th of an inch, which is the recommended size. Rafters are placed at a spacing of 24 inches, this accommodates the 5/8 thick plywood comfortably.

Oriental Standard Board (OSB) Vs. Plywood; Which Is Better For Roofing?

Oriental standard board (OSB) is a type of wood made up of strands of varying orientations compressed together with adhesive to form aboard. These boards are slowly gaining popularity in the roofing sector because of their low prices. Despite their low prices, they have some major drawbacks as it contains formaldehyde which may cause asthma. But, roofers still use them as they still meet many of the requirements of plywood used for roofing.

The most notable drawback of OSB is its inability to hold nails the same way plywood does. This affects the structural capabilities of the roof.

Roofing material should not absorb moisture; OSB does this and holds the moisture in for a long period. On the other hand, plywood may absorb moisture, but it will quickly dry up.

Here is a summary table relating OSB and plywood to help you make informed decisions when roofing:

OSB VS. Plywood

| Features | OSB | Plywood |

| Strength | Greatest shear strength compared to plywood | Less shear strength when compared to OBS |

| Grades | Available in various grades like OSB/4, OSP/3, OSB/2, and OBS/1 | Available in four main grades: A, B, C & D |

| Wood constitutes | 95 percent of wood & 5 percent resin and wax | 100 percent solid wood veneers |

| Market share | OSB holds 70-75 percent market share | Plywood accounts for 25 percent |

| Formaldehyde | It contains formaldehyde which may cause asthma | Less formaldehyde, thus reduced risk of asthmatic attack |

| Water test | Absorbs water when exposed to moisture | Best grades remain stable when exposed to water |

| Available sizes | Available in large panels of up to 16 feet | Not available in very large panels. Size limited to 8-10 feet |

| Price | Cheaper | Expensive |

What Is The Cost Of Roofing Per Square Foot?

The cost of roofing plywood 4 feet by 8 feet on average starts at 70 dollars and goes up to 100 dollars per sheet.

The price of plywood depends on the thickness of the sheet; the thicker the plywood, the more you will be charged. Thicker plywood is deemed to be more durable and damage-resistant.

How Many Sheets Of Plywood Do You Require For Roofing?

Given that the standard size of roofing plywood is 4 feet by 8 feet, you can calculate how many sheets you will need. The standard-size plywood will cover 32 square feet.

Most residential roofs are around 1500 square feet to 2000 square feet. This means that an average roof can take about 55 plywood sheets to have the job done.

Why Should You Use Plywood For Roofing?

Apart from plywood being low-cost and water-resistant, it has other advantages that make it a good roofing material.

Some of the other factors that make plywood a go-to roofing material include:

1. Strength

Plywood sheets are joined together and form a thick, strong sheet suitable for roofing. This helps support the rest of the roofing system.

2. It Is Easy To Work With

Plywood is easy to cut into smaller pieces that can perfectly fit the parts you want to be fixed in. You can also get a large sheet to cover a lot of room in just one swoop.

3. Durable

Plywood has uniform strength throughout the body and along the grain. When compared to other wood-made roofing materials, it comes out on top. During manufacturing, a lot of pressure is exerted on the sheets, making them have the ability to withstand more pressure than other roofing materials.

4. Tackles Big Projects

Standard-size plywood is large enough to cover a large area. This makes it very easy for plywood to use over big square feet of coverage.

5. Lightweight

Plywood is surprisingly very light for a piece of wood that size, considering the weight of trees. Its weight makes it easy to move to the roof and work with.

Disadvantages Of Plywood For Roofing

Even though plywood has many advantages, there are some drawbacks to using it as a roofing material. These are:

1. Low-grade plywood is porous and susceptible to water damage.

2. Wet wood is heavy, and it might damage your roof truces.

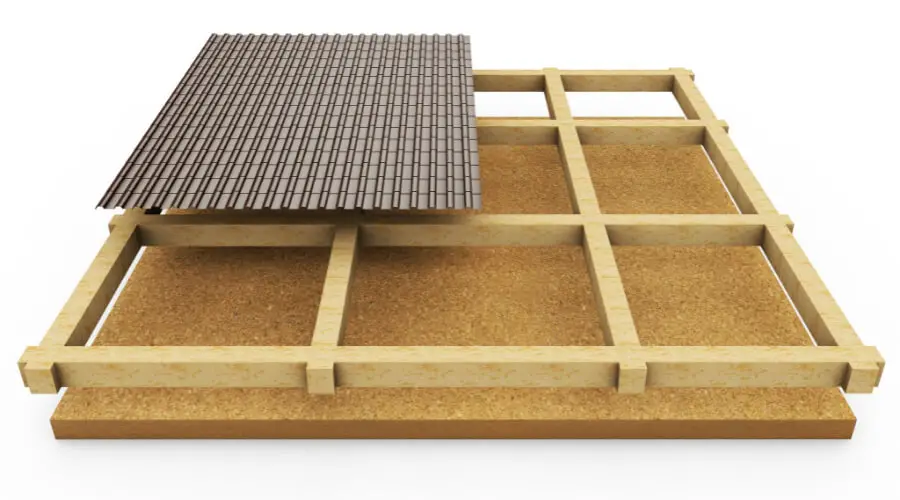

What Is Roof Sheathing?

Roof sheathing is a layer of plywood or OSB that covers the trusses and joists. Roof sheathing goes above the framework but below the roof shingles.

The sheathing is done to support the roof structure. The rigidity of plywood can redistribute weight onto the roof skeleton.

How Long Does Plywood Last On A Roof?

You cannot accurately state a specific period you expect plywood to last. External factors determine the longevity of plywood.

Some of these factors include:

1. Wood Quality

The better the wood used to make the plywood sheet, the better the end product’s quality.

2. Moisture

Wood that is constantly exposed to moisture without a chance of drying up is predisposed to reduced life expectancy.

3. Installation

When the plywood roof is done by a professional who follows all the required procedures, the roof will be more likely to survive for a longer period than once installed haphazardly.

4. The Climatic Condition In The Surroundings

Wood in cold areas or areas with high humidity will not survive longer than wood in hot and arid areas.

N/B: The life expectancy of a plywood roof should be at least thirty-five years when it is properly installed. In other cases, the roof can last over 50 years. For roof sheathing done with plywood, its life expectancy, thus, ranges from 30 to 40 years.

What Thickness Of Plywood Is Used For Roofing?

The minimum thickness of plywood for roofing is 3/8 inches. This is enough for a roof with 16-inch spaced rafters and the least roof load. Flatter roofs have a greater load, thus requiring thicker plywood, while steeper roofs have less load, and recommended minimum plywood thickness would work just fine.

Final Thought

Roofing is done using different materials. Plywood is one of these materials that can be used; it is cheaper and easier to use than the other materials. CBX or exterior plywood is the best for roofing. It is preferred since it does not absorb moisture and can endure different weather conditions.

References:

https://homeguides.sfgate.com/type-plywood-used-roofing-92306.html

https://www.h2ouse.org/plywood-for-the-roof/

Emma is a graduate of Domestic Science or Family and Consumer Sciences (Home Economics) from the University of Wisconsin. She has 7 years of experience Working with the strategic section of BestBuy and now writing full-time for Homeeon.

From Managing the Home, Interiors, Cleaning, and Exteriors to Gardening and everything about Making A Home Liveable – is her passion and this Homeeon is the result of this.

Emma loves decorating her home with the best stuff found online. She cares about quality over anything and writes reviews about them here in Homeeon. Get in touch with her over Pinterest.

Keep reading her blogs.